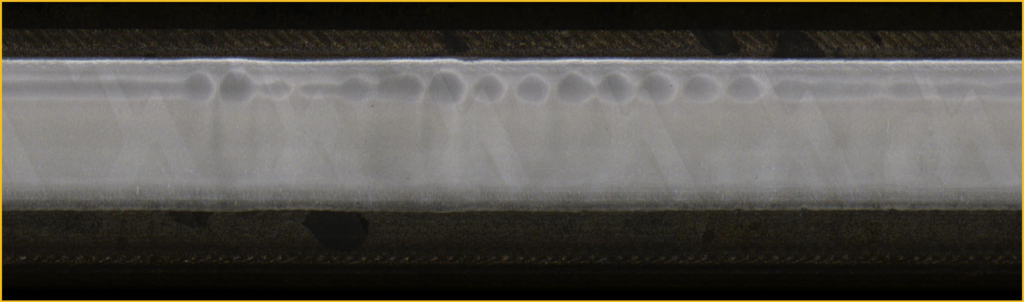

HRS System (High Resolution Surface) uses high-definition cameras to capture and record continuous, high-speed images of any surface or object with a resolution of up to 0.01 mm/px at speeds of up to 200 km/h.

In the railway sector, this technology is already employed on maintenance vehicles for fishplate diagnostics and other track components. In manufacturing, it is used for high-resolution defect detection on continuous production lines.

The system enables detailed inspection of any visible surface or component, from assembly assessment to the identification of surface defects such as:

Also by the means of artificial intelligence algorithms.

HRS helps to provide an evaluation of the object targeted with an accuracy of tens of microns in spite of any operation speed.