Rail Corrugation

Rail Corrugation

High-precision devices for measuring longitudinal surface defects

Corrugation refers to periodic, wave-like surface defects on the rail head that can lead to noise, vibration and accelerated wear of both the track and rolling stock.

To address this issue, ADTS offers two complementary solutions for rail corrugation detection, tailored to different inspection needs and platforms:

Laser-based systems for high-precision, profile-referenced analysis using triangulation and visual data

Eddy current sensor systems for fast, non-contact surface defect detection across multiple wavelength bands

These technologies are available in both portable trolleys and onboard configurations, supporting pre- and post-grinding inspections as well as continuous monitoring for maintenance planning.

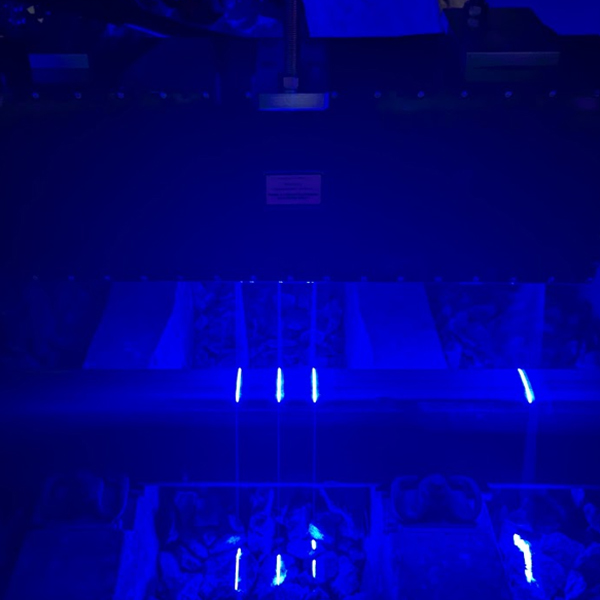

Laser Triangulation System

An optical, contactless measurement system designed for detailed analysis of rail surface corrugation. It uses a combination of lasers and high-resolution cameras to detect wavelength-based surface defects with high precision and stability.

| Measurement speed | Up to 30 km/h |

| Sampling step | Adjustable between 2–5 mm |

| Wave lenght (mm) | 30÷100, 100÷300, 300÷1000 |

| Reproducibility | ±30 μm (30–100 mm RMS); |

| Operating temperature | –25°C to +45°C |

RCM10 Sensors System

System based on eddy current sensors. Designed for grinding operations over long sections of track. Detects corrugation in frequency bands, suitable for periodic rail maintenance planning.

Wave Partner - Portable Trolley

A lightweight, fully automated trolley for non-contact rail corrugation inspection.

Equipped with eddy current sensors, it detects surface defects from 10 to 1000 mm in wavelength with micrometric precision.

Available in single or dual rail configurations, it offers real-time data visualization and post-analysis tools, making it ideal for both pre- and post-grinding inspections.