Rail Crack Detection

Rail Crack Detection

High-precision devices for measuring longitudinal surface defects

Rail integrity is critical for the safety and performance of railway infrastructure.

ADTS offers two complementary systems for rail crack detection, addressing both internal flaws and surface-level defects with high precision and reliability:

- UT System – Ultrasonic Testing

- Crack Eddy – Surface Crack Detection System

UT System – Ultrasonic Testing

A high-frequency ultrasonic inspection system for non-destructive detection of internal rail defects.

Installed onboard diagnostic vehicles, the UT System automatically identifies and localizes flaws such as:

Internal cracks

Inclusions and voids

Transverse and longitudinal defects

The system uses ultrasonic probes positioned on the rail surface to send and receive signals, analyzing wave reflections to map internal discontinuities. Ideal for preventive maintenance and in-service inspections, even at operational speeds.

Crack Eddy – Surface Crack Detection System

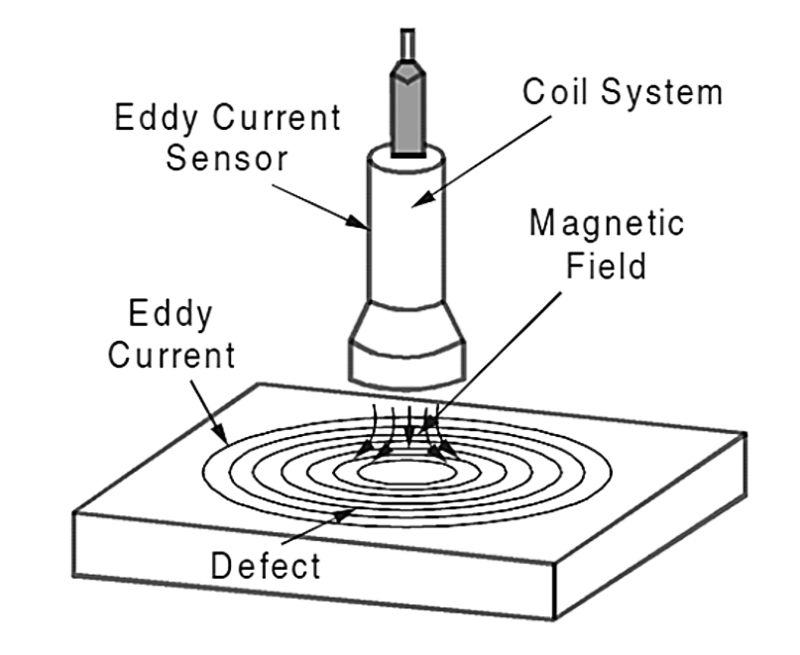

The Crack Eddy system operates using eddy current technology, which enables non-contact detection of surface and near-surface defects within the top 5 mm of the rail. The sensors generate a circular magnetic field that reacts to variations in material density, making it possible to identify cracks and discontinuities with high sensitivity and precision.

This makes Crack Eddy ideal for detecting:

Surface fatigue cracks

Head checking

Shallow sub-surface anomalies

Its compact design allows for easy integration with other ADTS diagnostic systems