The ADTS detection system of rail flaw detection vehicle is designed with the principle of ultrasonic flaw detection to detect internal defects in the steel rail. The system is fully integrated with the bogie of vehicle and consists of equipment on board and underframe. The detection mechanism underframe applies a dedicated bogie installation method with wheel type flaw detection. Six ultrasonic detector wheels are installed and 30 probes are integrated for ultrasonic excitation and reception. The vehicle is equipped with a signal processing system.

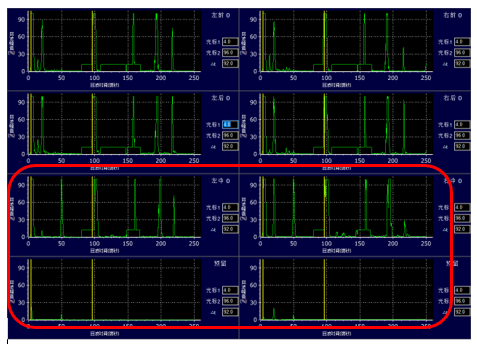

The computer is designed with a high-speed and high-performance industrial control computer, which is installed with the core flaw detection software. It can realize user’s terminal operation control and dynamic real-time display of defect results. The whole signal processing system can meet the parallel processing of ultrasonic signals, flaw feature signal extraction, multi-channel data space conversion, data