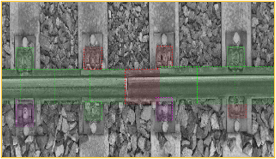

Installed underframe of a travelling or passenger train with the scope to inspect rail top surface, fastener and sleepers with automatic recognition of defect.

Track Surface Inspection System is a machine vision system composed by 3 boxes contact-less, installed on the bogie of the vehicle, one each left, right rail and centre line.

Track Surface Inspection system is able to automatically detect in real time mode:

• Missing Fastener; • Rotated Fastener; • Missing Bolts; | • Joint Gap; |

SIDE RAIL INSPECTION SYSTEM

Installed underframe of a travelling or passenger train with the scope to inspect side rail surface with automatic recognition of defect.

Side Rail Inspection System is a machine vision system composed by 4 boxes contact-less, installed on the bogie of the vehicle, two boxes for each rail.

Side Rail Inspection system is able to automatically detect in real time mode:

3D RECONSTRUCTION

Installed underframe of a travelling or passenger train with the scope to inspect side rail surface with automatic recognition of defect.

Fish Plate Inspection System is a machine vision system composed by 4 boxes contact-less, installed on the bogie of the vehicle, two boxes for each rail.