Track Imaging

Track Imaging

High-resolution imaging systems for high-speed railway inspection

HRS - High Resolution Surface

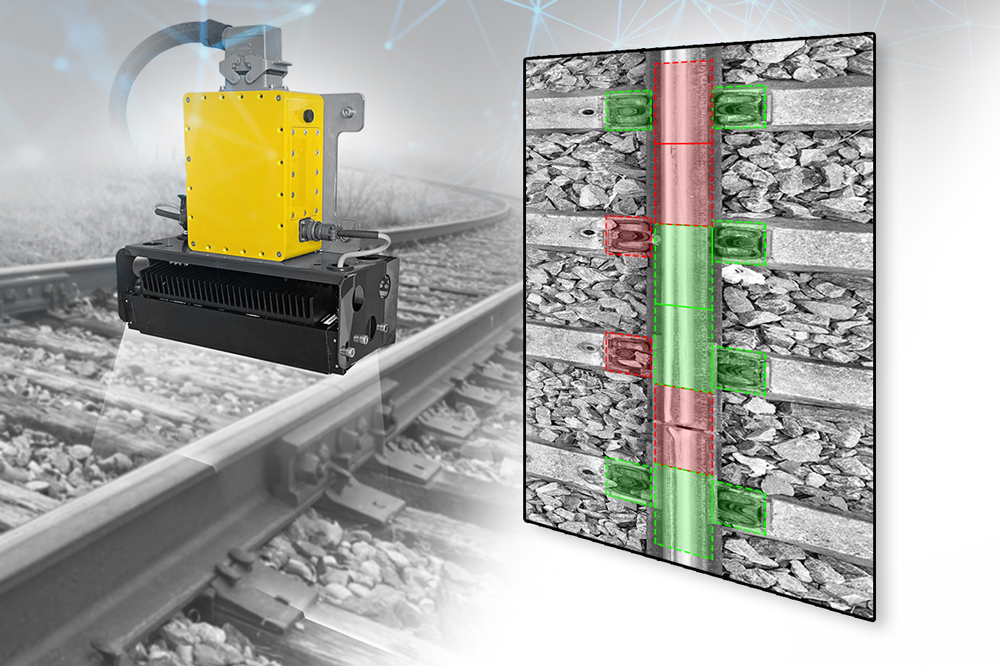

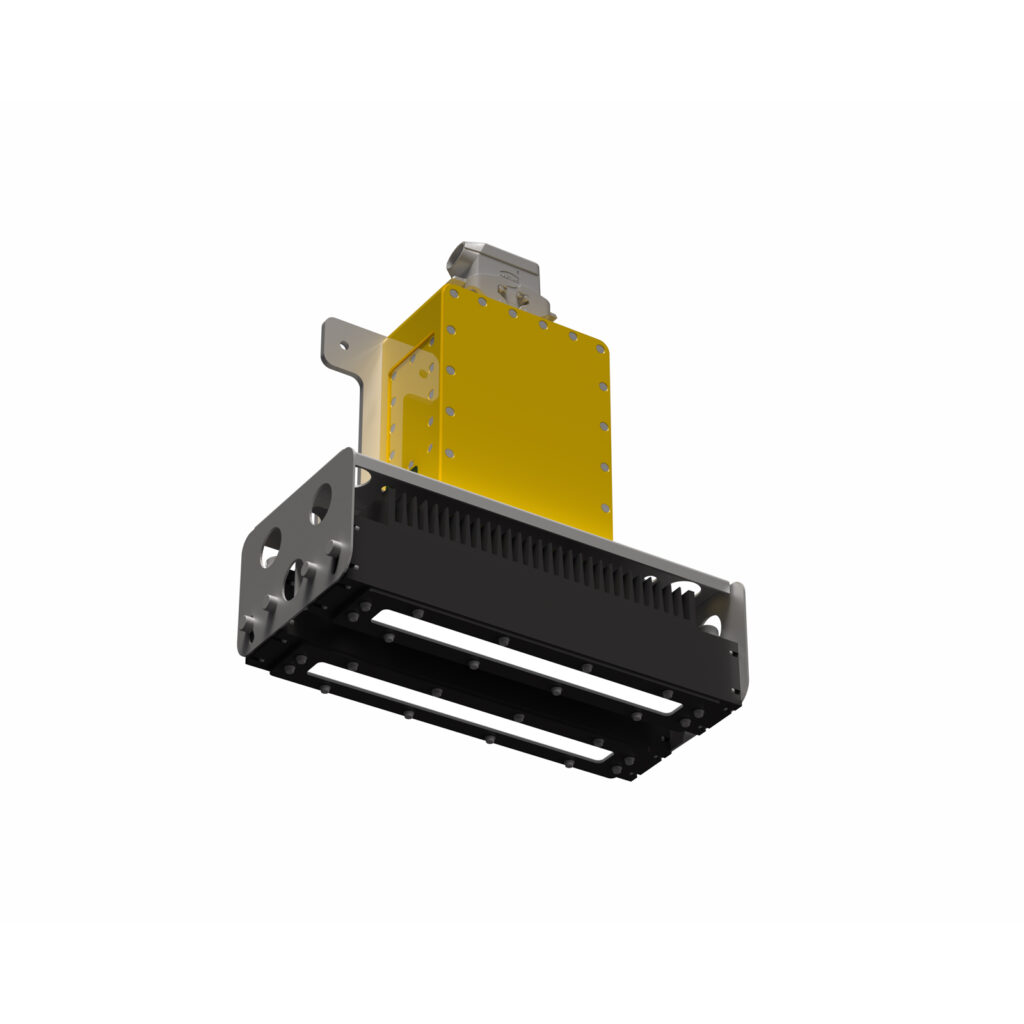

HRS (High-Resolution Surface) is a high-performance track imaging system designed for the detailed inspection of railway surfaces.

Equipped with high-definition line-scan cameras, it captures submillimeter images at high speed, making it ideal for the analysis of:

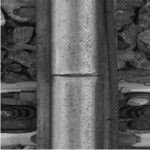

- Rails

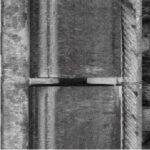

- Fishplates

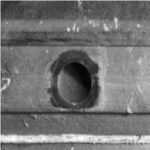

- Fasteners

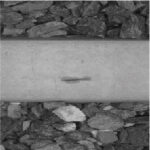

- Sleepers

- Ballast

- Other track components.

The system is fully adaptable and can be mounted on virtually any railway or inspection vehicle. Thanks to its adjustable orientation and proprietary lighting and synchronization architecture, HRS ensures optimal image acquisition even at full operating speed, with microsecond-level timing accuracy.

AI-Enhanced Inspection

Proprietary software allows data to be collected and analyzed either directly from the vehicle’s control cabin or remotely from a separate location.

Integrated artificial intelligence empowers the HRS system to autonomously detect and assess:

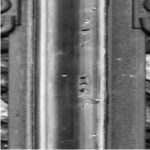

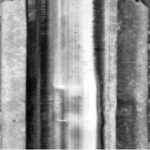

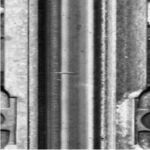

- Cracks and surface defects;

- Presence and alignment of components;

- Deformations and wear;

- Structural integrity indicators.

Defects Catalogue

Models

HRS

High-resolution imaging

for targeted rail inspection.

| Resolution | 0,05 mm/px |

| FOV | ca. 300 mm |

HRSW

Full-track coverage with multiple synchronized units.

| Resolution | 0,1 mm/px |

| FOV | ca. 600 mm |

V3DS

Integrates laser triangulation for enhanced 3D imaging.

| Resolution | 0,1 mm/px |

| FOV | ca. 600 mm |

Configurations

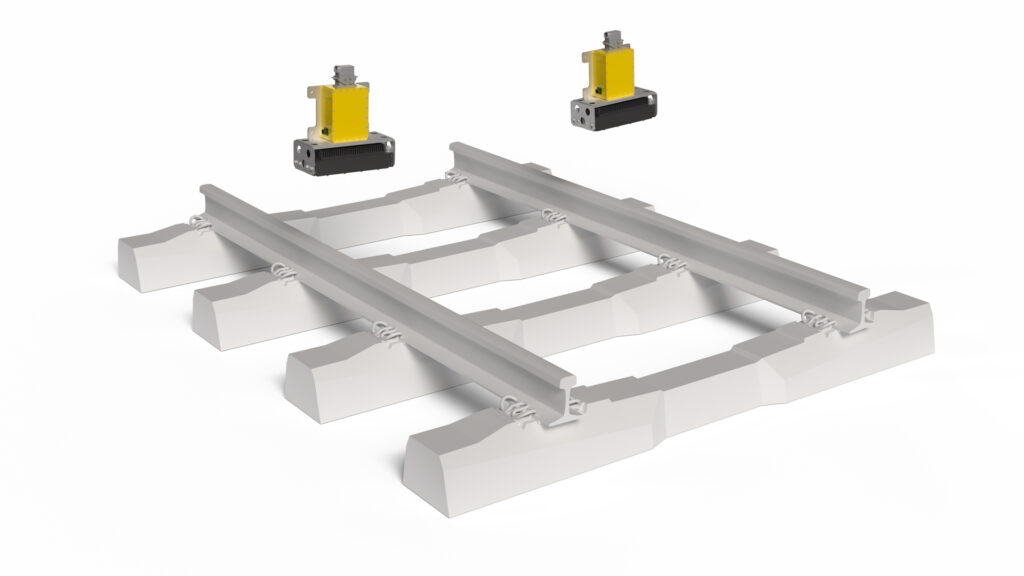

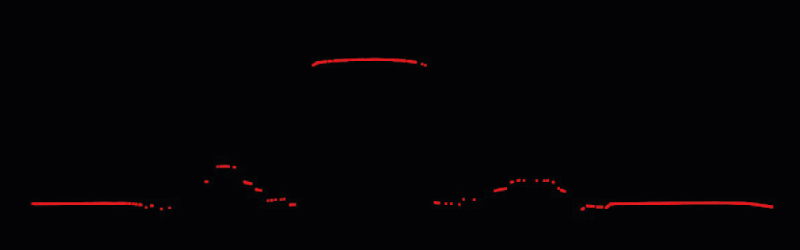

Rail Surface

Devices:

2 x HRS

Defects detection:

Rails

Rail Side

Devices:

2 x HRS

Defects detection:

Fishplates

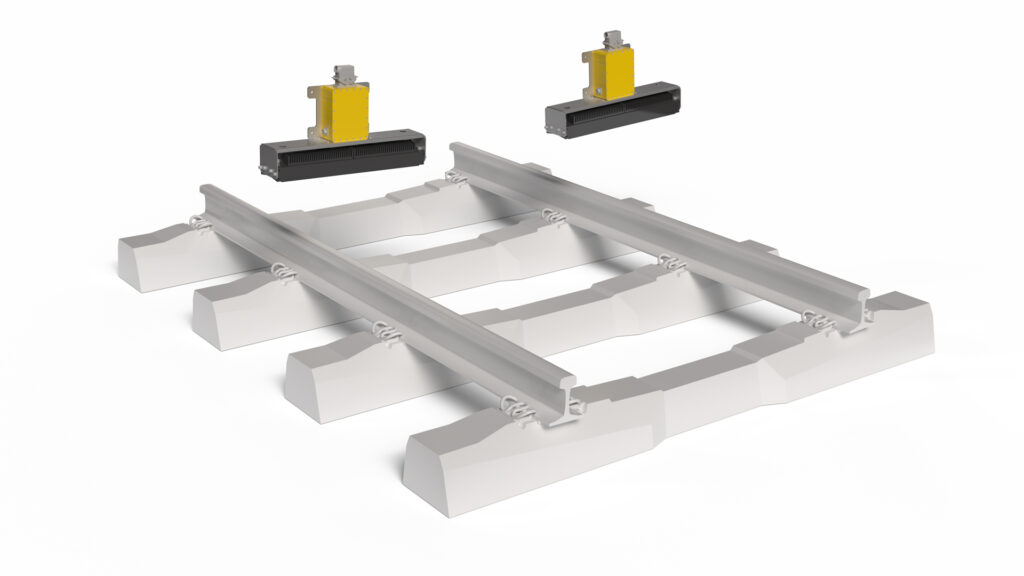

Rail View

Devices:

2 x HRSW

Defects detection:

Rails

Fasteners

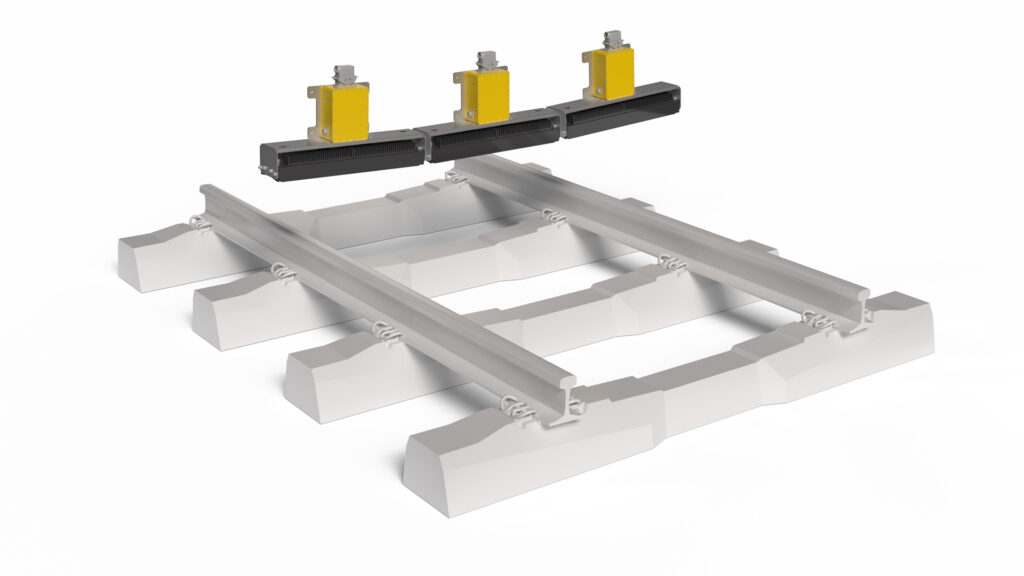

Full Track

Devices:

3 x HRSW

Defects detection:

Rails

Fasteners

Sleepers

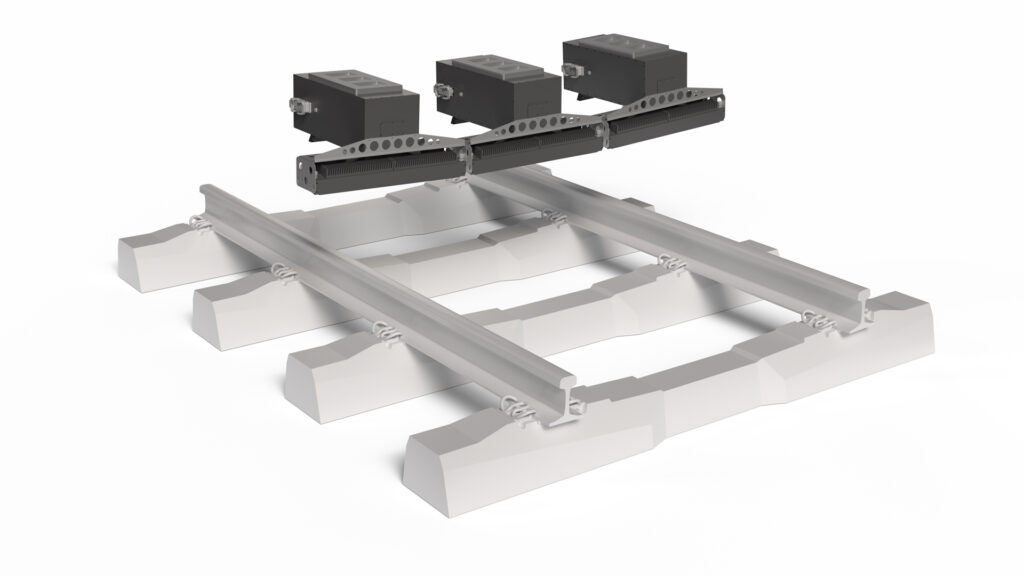

3D Full Track

Devices:

3 x V3DS

Defects detection:

Rails

Fasteners

Sleepers

Ballast

The 3D Full Track configuration, with three V3DS units, enables the simultaneous acquisition of 3D shape profile and high-resolution images of the railway track’s, which are then correlated through dedicated analysis software.

Our Projects

Railway Inspection System for Metro Taipei

IAF Münster 2025 – Showcasing Innovation in Track Monitoring

Track Imaging System for Line Inspection Vehicle

Downloads

- High Resolution Surface (HRS) – Brochure PDF